Every plastic manufacturing facility in Florida faces a unique set of risks and challenges. The state’s robust manufacturing sector, which supports everything from large-scale production plants to specialized plastic product lines, demands careful risk management planning and comprehensive insurance solutions tailored to its needs. Factories, distribution centers, and small production facilities share common concerns such as property damage, equipment failures, business interruptions, and liability exposures. With a track record of thriving business establishments and substantial payroll employment, Florida’s plastic manufacturing industry stands as a cornerstone of the state economy.

As the manufacturing landscape continues to evolve and regulatory changes influence coverage requirements, keeping insurance policies updated with the latest market trends is more important than ever. According to recent data from

Beautify Data LLC, there were 373 private business establishments in Q2 of 2024 in the All Other Plastics Product Manufacturing Industry in Florida. This figure speaks volumes about the concentration and scale of operations within the state.

Florida’s Expansive Plastic Manufacturing Landscape

A Closer Look at the Industry Trends

Florida hosts a diverse range of plastic manufacturing facilities. The sector is not only known for its volume but also for its versatility. Specialized sub-industries like Plastics Product Manufacturing and Plastics Wholesaling offer distinct services that boost the state's economy. In August 2024, the private payroll employment for the broader Plastics Product Manufacturing Industry reached 12,106, demonstrating a sizable workforce specifically trained for the complexities of plastic production (Beautify Data LLC).

Diverse production lines inevitably result in varied insurance needs. Facilities engaged in high-volume production require coverage that addresses large claims scenarios, while smaller operations might concentrate on cost-effective policies that still provide adequate protection. Balancing these factors often involves working closely with experienced brokers and insurers who understand the complexity of the plastic manufacturing field.

Workforce and Economic Contributions

The strength of Florida’s plastic manufacturing sector is also measured by its employment figures and economic impact. For instance, in September 2024, the private payroll employment within the narrow subset of Other Plastics Product Manufacturing peaked at 5,338 jobs (Beautify Data LLC). These jobs cover an array of roles from production line workers to management and technical staff, each playing an integral role in the operational chain.

Beyond employment, industry profitability and contributions to the state’s GDP prove to be essential elements for insurers to consider. Florida's overall Real Gross Domestic Product for Plastics and Rubber Products Manufacturing stood at $1,537.6 million in 2024. This figure not only highlights the scale of the operations but also emphasizes the significance of investing in high-quality insurance coverage to protect these economic assets.

Understanding the Risks in Plastic Manufacturing Facilities

Risks Associated with Production Processes

Manufacturing plastics involves a series of intricate processes. High temperatures, volatile chemicals, and sophisticated machinery create ample opportunities for accidents and malfunctions in production facilities. Material handling errors, equipment failure, or unexpected chemical spills can lead to significant business interruptions or property damage. These risks necessitate a comprehensive insurance policy capable of covering specialized liabilities and offering coverage for events unique to this sector.

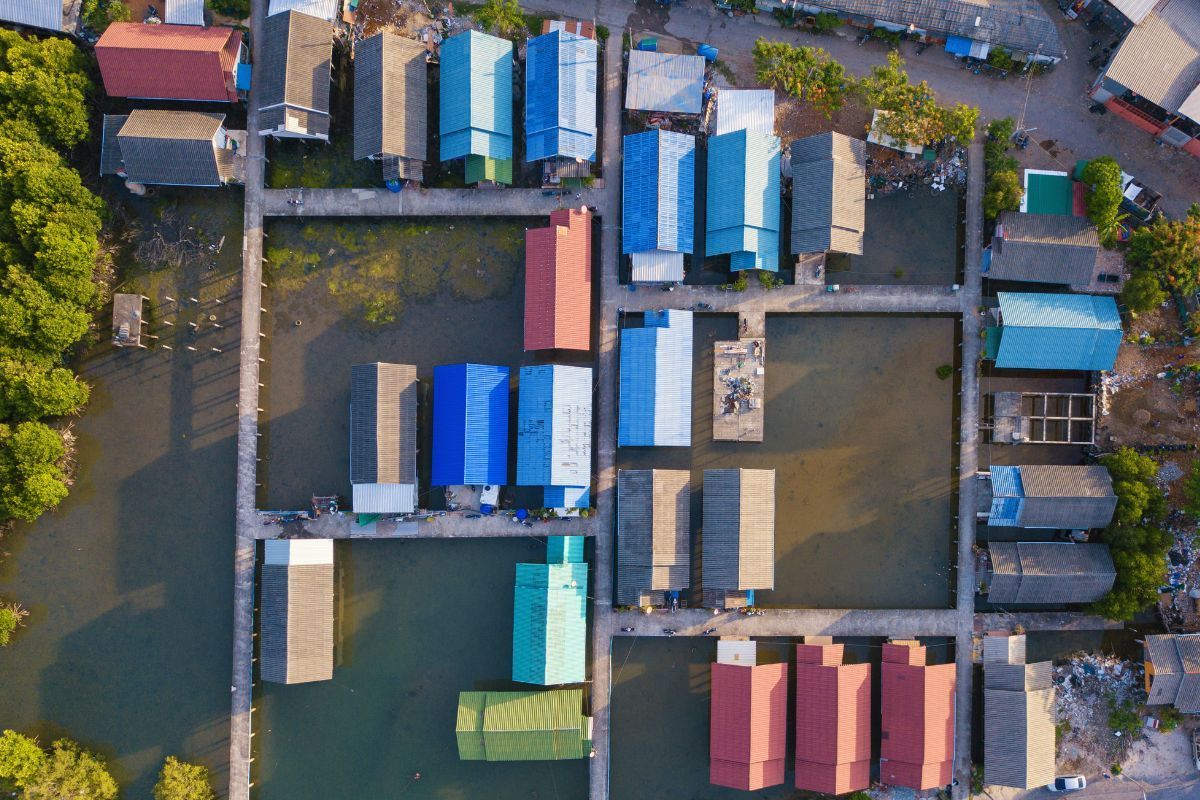

Facilities may experience physical damage from equipment breakdowns or natural effects such as flooding, especially in low-lying areas of Florida. Likewise, the potential for employee injury during physically demanding tasks further underscores the need for robust workers compensation policies along with general liability and property insurance solutions.

Additionally, differences between segments like Plastics Product Manufacturing and Plastics Wholesaling mean that each sub-sector may have its own set of risks. For example, the Plastics Wholesaling industry, made up of 196 establishments that employ over 1,100 people (IBISWorld), must consider risks related to logistics, inventory management, and customer distribution. Tailored policies ensure that wholesalers have coverage that addresses their specific operational hazards.

Regulatory Compliance and Environmental Concerns

Environmental regulation plays a pivotal role in the plastic manufacturing industry. With increasing governmental scrutiny and regulatory oversight for emissions, handling of waste products, and chemical usage, companies must invest in environmental liability insurance. In Florida, particular attention is paid to compliance with state-specific rules that seek to mitigate pollution risks. In this context, companies can shield themselves from potentially high fines and cleanup costs through effective environmental coverages.

Regulatory compliance extends to workplace safety protocols as well. Insurers work closely with facilities to assess risk management practices and assist in implementing safety strategies that not only protect the workforce but also reduce the likelihood of insurance claims. This proactive involvement promotes a safer work environment and may help facilities qualify for lower premiums.

Manufacturers also face strict standards for product quality. If a product fails or causes harm due to defective manufacturing or design flaws, liability claims could jeopardize the financial stability of a business. A well-structured general liability policy is a must-have since it offers protection in cases of claims related to bodily injury or property damage caused by faulty products.

Insurance Solutions Tailored to Florida’s Plastic Manufacturers

Customized Coverage Options

When choosing insurance for plastic manufacturing facilities, one size does not fit all. Insurers need to provide policies that are flexible enough to account for various aspects such as operation size, location, and production lines. With some facilities employing over 12,000 workers in the broader plastics manufacturing segment (Beautify Data LLC), the risk profile can be vastly different from that of a small specialized manufacturer.

Comprehensive policies often bundle property, general liability, product liability, equipment breakdown, and environmental insurance. For many facilities, the importance of including a business interruption clause cannot be overstated. In a scenario where a facility faces downtime due to a mechanical failure or an accident, ensuring that ongoing financial commitments are met is critical to maintaining stability.

Insurance providers frequently emphasize an integrated approach. This means carrying a mix of coverages that not only secure the facility’s physical assets but also protect future revenue streams and the overall integrity of the business. Manufacturers are advised to undergo periodic risk assessments that audit current policies against evolving operational practices.

Case Studies and Best Practices in Risk Management

Case studies of Florida-based plastic manufacturing facilities have shown that proactive risk management and customized insurance solutions are the keys to long-term success. A facility employing over 12,000 employees with total annual wages nearing $820 million in the plastics product manufacturing sector (American Chemistry Council) found that investing in regular safety training and equipment upgrades contributed directly to fewer operational disruptions.

Best practices often include conducting internal audits for compliance with OSHA standards and maintaining clear documentation of safety measures. Some companies have implemented digital monitoring systems that track equipment health in real time. These forward-thinking strategies not only decrease the occurrence of accidents but can strengthen an insurer’s willingness to offer lower premiums or more extensive coverage options.

In many cases, partnerships between manufacturers and specialized insurers create opportunities for ongoing risk analysis. Automated safety systems, combined with professional periodic reviews, encourage constant dialogue between insured parties and their providers. Such collaborative efforts result in policies that adapt to changes in the operational environment over time.

The Economic Impact of Florida’s Manufacturing Sector

A Broader Economic Perspective

Manufacturing is a cornerstone of Florida’s economic development. In 2023, Florida’s manufacturing employment reached 420,687, marking a noticeable increase from the previous year (Florida Department of Economic Opportunity). This steady growth underscores the vitality of sectors such as plastic manufacturing and emphasizes the need for well-structured risk and insurance management.

The manufacturing sector in Florida contributes significantly to the state’s GDP. In fact, in 2022, the manufacturing sector contributed more to the state’s economic output than industries such as tourism, agriculture, and transportation (Florida Department of Economic Opportunity). This economic rationale drives the importance of protecting manufacturing facilities with insurance that covers both tangible and intangible assets.

With business establishments totaling 25,594 and job numbers exceeding 420,000 in the broader manufacturing arena, every dollar invested in risk mitigation translates directly into sustained economic output and job security for local communities. Financial stability in the manufacturing sector means continued innovation, expansion, and the ability to weather unexpected downturns.

Wage Dynamics and Investment in Risk Management

Employees in Florida’s manufacturing sector command higher wages relative to many other industries. On average, the wage premium is about $10,835 more than in other sectors (Florida Department of Economic Opportunity). This wage differential reflects the specialized skills and responsibilities inherent in manufacturing roles, including those in the plastics sector. Such relatively high wages underscore the need for robust workers compensation and liability coverage to protect highly paid workers and the companies that employ them.

Manufacturers in Florida have a vested interest in safeguarding their investments-not just in the physical operations but also in the human workforce. Insurance policies that effectively cover worker-related risks help companies maintain financial stability and mitigate operational disruptions that can affect the bottom line.

In this competitive landscape, the benefits of comprehensive insurance options are clear. Companies that invest in tailored risk management solutions are better positioned to reallocate resources toward growth and innovation, which in turn bolsters the overall strength of the manufacturing industry across the region.

Policy Considerations and Coverage Options for Plastic Manufacturers

Essential Coverage Components

Plastic manufacturing facilities in Florida should evaluate several critical aspects when selecting an insurance package. Core elements of an effective policy typically include property coverage for buildings and equipment, general liability for accidents, product liability for defects or failures that may lead to claims, and business interruption policies tailored to manufacturing-specific disruptions.

Each coverage component must be carefully reviewed. For example, property damage is not just limited to physical losses from fires or floods but may extend to equipment malfunction or even supply chain interruptions that affect production. Given the prevalence of 373 private business establishments in some specialized plastic manufacturing sectors (Beautify Data LLC), every nuance in coverage can prove critical in minimizing losses.

Product liability insurance is of particular importance. With products often destined for varied applications-and sometimes even critical infrastructure roles-a failure in product quality can lead to significant lawsuits or recalls. Insurers in this field are increasingly offering specialized packages that address the intricacies of production methods and quality control systems inherent to plastic manufacturers.

Risk Mitigation and Technology Integration

The integration of technology in risk management is transforming how plastic manufacturers manage operational hazards. Real-time monitoring systems on the production floor can alert managers of equipment degradation or abnormal patterns that precede a potential breakdown. This forward-thinking approach not only minimizes downtime but may also result in insurance discounts or more favorable policy terms.

Digital technologies like sensors and data analytics provide real-time insights into process performance, equipment health, and even environmental factors that could lead to hazards. Insurers often collaborate with manufacturers in deploying these advanced monitoring systems. These systems serve as a proactive measure to mitigate the frequency and severity of claims, thereby aligning the interests of both the insurer and the insured.

Regular investment in technology and risk management not only secures physical assets but also contributes to the overall operating efficiency of the facility. This proactive stance is an attractive trait for insurance companies, enabling them to offer policies that are both comprehensive and economically viable for manufacturers.

Impact of State and National Trends on Plastic Manufacturing Insurance

The Role of Economic Growth and Regulatory Changes

Economic growth in the manufacturing sector is tightly interwoven with advances in technology and production methods. In Florida, the manufacturing GDP has experienced significant growth over the past decade. This robust growth has far-reaching implications, including influencing the structure of insurance policies. As companies expand, the complexity of operations also increases, making it important to continually reassess risk exposure and coverage needs.

Regulatory changes at both state and national levels require manufacturers to stay current with policy updates that affect labor, safety protocols, and environmental control. Insurance providers often update their offerings to incorporate changes in regulatory environments. For instance, when new OSHA guidelines or environmental regulations are introduced, policy terms may be revised to help factories meet compliance requirements without risking significant financial exposure.

National trends also indicate a shift toward more specialized policies that offer integrated solutions. These trends benefit Florida's plastic manufacturers by providing policies that are not only more relevant to their operational realities but also more adaptive to the evolving risk environment.

State-Specific Factors Affecting Policy Choices

Florida’s unique geographic and economic environment influences policy choices. Frequent exposure to extreme weather events, such as hurricanes and heavy rains, requires that manufacturers invest in insurance that provides extensive property and business interruption coverage. Facilities located in coastal regions often deal with additional risks such as flooding and storm damage. These inherent conditions necessitate specialized, sometimes add-on, coverages that mitigate weather-induced losses.

In addition, Florida’s competitive business climate and significant plastics output demand attention to workflow and process-specific risks. With over 420,000 manufacturing jobs reported in 2023 (Florida Department of Economic Opportunity), the pressure to maintain continuous production is high. Insurers often work with businesses to design policies that minimize downtime and provide rapid claim resolutions, helping manufacturers resume operations quickly after an incident.

Moreover, incentives and state-specific programs sometimes offer guidance to manufacturers on how to better manage property risks, relate with local mitigation measures, and ultimately lower their premiums. This type of tailored advice is a hallmark of effective risk management and insurance planning in the Florida market.

Benefits of Specialized Insurance Policies for Plastic Manufacturers

Financial Security and Operational Resilience

One of the primary benefits of specialized insurance policies is the financial security they offer in times of crisis. For a facility operating with multi-million-dollar payroll budgets and significant capital investment, business interruptions can translate into substantial loss. Policies that include business interruption coverage help replace lost income while a facility is being restored. Such coverage is crucial in preventing a temporary disruption from escalating into long-term financial instability.

Integrated policies that also address general liability and environmental risk protect manufacturers from lawsuits and other liabilities that can result from production defects or accidental releases of chemicals. These comprehensive solutions allow the management team to focus on operational improvements and scaling business operations, knowing they have a robust safety net to fall back on.

Beyond immediate crisis management, effective insurance solutions contribute to overall operational resilience. This resilience means that companies can invest in new technology, expand production capacity, and pursue innovative product lines with the confidence that they are protected against unforeseen disruptions.

Enhanced Competitive Position in the Marketplace

Manufacturers that invest in specialized insurance solutions often find themselves with a competitive edge. A well-insured facility is more likely to be considered a stable, reliable partner for large contracts and supply chain agreements. Large clients and distributors look for consistent production capabilities and risk mitigation strategies before entering into business relationships.

An attractive portfolio of tailored insurance policies not only enables smoother claim processes but also demonstrates a company’s commitment to risk management. This, in turn, can boost investor confidence and open up opportunities for favorable financing conditions. With industry giants employing around 12,030 workers and generating nearly $820 million in wages in the Plastics Product Manufacturing sector (American Chemistry Council), having a robust insurance portfolio is not merely an expense-it’s an investment in long-term business stability and growth.

Further, insurers often reward clients who adopt forward-thinking risk mitigation practices with lower premiums or enhanced coverage terms. The integration of proactive safety measures, such as mandatory training sessions and modernized production equipment, can lead to cost savings while improving overall manufacturing efficiency.

Practical Guidance on Choosing the Right Policy

Assessing Individual Business Needs

Every plastic manufacturing facility is unique. When evaluating insurance needs, it’s important to start with a comprehensive risk assessment. Key factors include the facility's production volume, the type of plastics produced, machinery in use, staffing levels, historical claim data, and geographical risks specific to the location. Investors and managers should take stock of all these elements before engaging with potential insurers.

A thorough review of existing safety measures and disaster recovery plans can also provide insights into which areas might require additional coverage. For example, if a facility has state-of-the-art monitoring systems that reduce the risk of equipment failure, this may be an opportunity to negotiate more favorable terms with insurers. Business owners who understand their risk profiles are better positioned to choose policies that align with their operational realities and financial constraints.

Ensuring that policies include sufficient coverage for both short-term interruptions and long-term liabilities will prove vital over the course of any manufacturing disruptions. This nuanced approach to insurance selection can help companies strike a balance between cost containment and comprehensive protection.

Partnering with Experienced Insurance Providers

Engaging with insurers who specialize in manufacturing is often the best course of action. Experienced brokers understand the intricacies of modern plastic manufacturing, from production processes to environmental challenges. They can offer tailored advice that adjusts for the rapid pace of technological change and evolving regulatory requirements.

Many industry-specific insurance carriers collaborate directly with manufacturing facilities to create policies customized for their operational risk profiles. This level of detail in coverage design is invaluable when unexpected events occur. Manufacturers who partner with experts generally benefit from enhanced customer service, smoother claims processes, and eventually, lower premiums. This partnership approach is critical for businesses that want to optimize the balance between cost and comprehensive protection.

Manufacturers are encouraged to review their policies on an annual basis. This regular evaluation helps to accommodate changes in business size, production methods, and emerging risks. Managers should stay informed by engaging in industry forums and consulting with risk management experts to align their insurance solutions with best practices and new economic realities.

Frequently Asked Questions

Q: Why is specialized insurance important for plastic manufacturing facilities?

A: Specialized insurance addresses the unique risks inherent in plastic manufacturing, including property damage, equipment breakdown, product liability, and environmental hazards. It ensures that facilities have tailored protection that supports business continuity during unexpected events.

Q: What types of coverage should a plastic manufacturer in Florida consider?

A: Key coverages include property insurance, general liability, product liability, environmental liability, equipment breakdown, and business interruption policies. These components work together to offer comprehensive protection for both the physical assets and operational revenue streams.

Q: How do recent economic trends affect insurance policies in manufacturing?

A: Growth in manufacturing output, increases in employment, and higher wage levels all contribute to risk profiles that insurers consider when designing policies. Economic expansion can lead to specialized policies that factor in advanced risk mitigation strategies and evolving regulatory requirements.

Q: Can technology help reduce insurance premiums for plastic manufacturers?

A: Yes. Investing in technology, such as real-time monitoring and automated safety systems, can reduce the frequency and severity of claims. This, in turn, may lead insurers to offer lower premiums or enhanced coverage terms.

Q: How often should insurance policies be reviewed and updated?

A: It is advisable to review insurance policies annually or whenever significant changes occur within the business. Regular updates ensure that coverages remain current with evolving operational risks and safety measures.

Q: What role does environmental liability insurance play in the plastics sector?

A: Environmental liability insurance is crucial for covering the costs associated with accidental chemical spills, regulatory fines, and cleanup efforts. It is particularly important in an industry where handling volatile chemicals is a daily practice.

Q: Are there benefits for manufacturers who proactively manage their risks?

A: Manufacturers that adopt proactive risk management measures often benefit from lower insurance premiums and improved policy terms. Demonstrating a commitment to safety and operational excellence can help build a strong case for insurers to provide cost-effective coverage.

Wrapping Things Up

The plastic manufacturing industry in Florida is characterized by both its dynamic production capabilities and the sophisticated risk management challenges that come with them. From tailored policies that combine traditional property and liability coverages with specialized business interruption and environmental components, Florida manufacturers have many options to secure their operations. Strategic risk assessments and investments in innovative safety measures can protect businesses against financial shocks while positioning them for growth.

By leveraging expert guidance from insurers experienced in the plastics sector, manufacturing facilities can build sustainable operations that not only meet demand but also excel in safety and economic resilience. With Florida’s manufacturing landscape continually expanding-with employment numbers in key sub-sectors and significant contributions to the state’s GDP-the importance of comprehensive insurance coverage cannot be overstated.

Facilities that integrate technology, foster ongoing risk evaluations, and partner with knowledgeable insurance providers will enjoy greater operational stability. In an industry with substantial economic output, robust protection is not merely a safety net. It is a competitive advantage that supports innovation, secures investments, and drives long-term business growth. As Florida continues to lead in manufacturing output, proactive insurance strategies will remain a vital component of the industry’s overall success.

Final Thoughts on Insurance for Florida Plastic Manufacturers

Developing a thorough understanding of the associated risks and opportunities in the plastics manufacturing sector is crucial for any business in the field. Each facility has its own set of challenges-from equipment vulnerabilities to environmental impact-and a one-size-fits-all insurance policy will rarely suffice. Specialized coverage offers a safeguard to ensure that manufacturing operations can withstand unforeseen disruptions while continuing to generate economic value.

Stakeholders are advised to carefully analyze their operations and collaborate with insurance professionals well-versed in manufacturing nuances. Such expertise helps in designing a policy that is both comprehensive and adaptive to regulatory and technological changes. With tailored policies, manufacturers can maintain production continuity, protect their workforce, and secure their investments against the risks inherent in the dynamic plastics market.

Florida’s manufacturing sector, with its significant employment numbers and robust economic contributions, exemplifies the need for detailed and proactive insurance planning. Facilities that invest in risk management today are not only ready to handle unexpected events, but they also set a strong foundation for future growth. Ultimately, effective insurance solutions empower manufacturers to focus on what they do best-producing high-quality plastic products while safeguarding their businesses against uncertainty.

ABOUT THE AUTHOR: PAUL RAMENTOL

I am the Owner and President of Mesa Insurance Agency. I help individuals and business owners across Florida secure personal and business insurance coverage that supports their needs. My focus is on clear guidance, direct communication, and long-term support without call-center delays or confusion.

Contact Us

Personal Coverage Options

Insurance Built for Everyday Protection

Mesa Insurance Agency provides personal insurance coverage designed to support daily life. Our team reviews risks and coverage needs to help clients secure dependable protection at fair rates.

Dental & Vision Insurance

Coverage that helps manage routine dental and vision care costs.

Business Coverage Options

Insurance Built for Business Protection

Mesa Insurance Agency provides business insurance coverage that helps protect operations, employees, and property. We work with multiple carriers to offer coverage options that support daily business activities and long-term stability.

Commercial Auto Insurance

Coverage for business-owned vehicles, drivers, and accident-related liability exposure.

General Liability Insurance

Protection against third-party injury, property damage, and common business liability risks.

Professional Liability Insurance

Coverage for claims related to professional services, advice, or service errors.

Workers’ Compensation Insurance

Coverage that helps support employees with work-related injuries and medical costs.

Commercial Property Insurance

Protection for buildings, equipment, inventory, and physical business assets.

Errors & Omissions Insurance

Coverage for financial losses caused by mistakes, omissions, or service-related claims.

Industries We Serve

Serving Businesses Across Multiple Sectors

Mesa Insurance Agency works with business owners across Florida to provide insurance coverage that supports daily operations. We understand common risks faced by different industries and help clients secure reliable protection.

Construction and Trades Insurance

Coverage for job sites, vehicles, tools, and workplace risks.

Hospitality Businesses Insurance

Insurance for restaurants, bars, and service-based operations.

Retail and

Commercial Properties

Protection for storefronts, inventory, and customer-related liability.

Our Approach

Insurance Made Easy to Understand

Mesa Insurance Agency provides business insurance coverage that helps protect operations, employees, and property. We work with multiple carriers to offer coverage options that support daily business activities and long-term stability.

What makes Mesa Insurance Agency different?

We are an independent agency with access to multiple carriers. This allows us to offer flexible coverage options.

Clients work directly with licensed agents. Service continues beyond the policy start date.

Do you offer coverage for individuals and families?

Yes. We provide personal insurance for individuals and families across Florida.

Coverage includes auto, home, health, life, and flood insurance. Our team explains each option clearly.

Do you work with small and mid-sized businesses?

Yes. We work with businesses of many sizes and industries.

Our team helps identify risks and secure appropriate coverage. Ongoing service is included.

Can I make changes to my policy later?

Yes. Policies can be updated as needs change.

We assist with coverage adjustments, additions, and removals. Clients can contact us directly for help.

Is flood insurance required in Florida?

Flood insurance is not always required, but it is strongly recommended in many areas.

Standard home insurance does not cover flood damage. Our team can review your flood risk and options.

How do I contact your office?

You can contact us by phone, email, or through our website.

Our team responds promptly during business hours. Support is always available when needed.

From the Blog

Insurance Topics That Matter

Clear answers for common questions.

Client Reviews

Trusted by Clients Across Florida

Mesa Insurance Agency is proud to serve individuals and businesses throughout Florida. Clients choose us for clear communication, responsive service, and reliable insurance support. Their feedback reflects our focus on long-term relationships and consistent service.

Contact Us