An unexpected machinery breakdown during peak production hours or a sudden storm taking a toll on state-of-the-art bottling units can put operations on hold for days. In Florida, where the beverage industry fuels a multi-billion-dollar economy, safeguarding packaging and bottling plants is not just a matter of compliance but of survival. Industries here face unique challenges ranging from weather volatility to rising reinsurance costs, so choosing the right insurance coverage becomes imperative. Learn more about the economic impact of this thriving industry via the Florida Beverage Association.

This article explores the intricacies of packaging and bottling plant insurance, offering insights into coverage needs, risk management, and regulatory changes impacting the industry. With Florida's market being both dynamic and frequently challenged by unpredictable events, a well-structured insurance plan not only covers losses but ensures business continuity.

Coverage essentials addressed here will help plant operators and facility managers understand the risks associated with their operations, along with how comprehensive policies and careful planning can protect both physical assets and operational revenue.

Understanding the Need for Specialized Insurance

Packaging and bottling plants in Florida operate in a complex environment that requires tailored insurance policies. There are several factors at play, including the significance of Florida's beverage industry, which is responsible for a sizable economic impact annually. As reported by sources like the Florida Beverage Association, the industry's contribution exceeds simple production numbers – it is a major driver of economic stability.

Insurance programs need to address physical damage to facilities, business interruption issues, liability exposures, and potential product recalls. Factors specific to bottling operations include high-value machinery, significant inventory, and specialized storage conditions. These assets and risks require a bespoke approach that differs from generic property insurance policies.

Plant owners should recognize that a standard commercial policy may leave gaps in coverage. As such, considering endorsements specific to bottling operations is essential to safeguard against financial exposures that can result from production halts and regulatory non-compliance.

Key Components of Coverage for Packaging and Bottling Plants

Property and Equipment Protection

Given the heavy investment in specialized bottling and packaging equipment, property coverage is a necessity. A typical policy should include coverage for machinery breakdown, equipment replacement, and repair costs. For many facilities in Florida, the cost of reinsurance has become a significant factor, as industry experts have noted that "the cost of reinsurance skyrocketed" (Locke Burt, Security First Insurance).

Equipment-specific endorsements not only cover repairs but also potential losses from operational downtime. Rising reinsurance costs reportedly contributed to operational stress on policies across the state, and the inclusion of tailored endorsements ensures that bottling plants have a cushion against these spikes. As reinsurance terms evolve, operators must maintain open dialogue with insurers to ensure the latest risks are covered.

This level of detail in coverage helps manage expenses related to unexpected equipment failures and accelerates recovery times, ensuring that production can continue with minimal disruption.

Business Interruption and Loss of Income

An unplanned shutdown can quickly morph into a significant financial setback for any bottling operation. Business interruption insurance covers lost income resulting from a shutdown due to insured perils such as natural disasters or equipment failure. Given the frequency of extreme weather events in Florida, this type of coverage is indispensable.

For example, unpredictable weather conditions can force temporary closures, leading to delayed orders and lost revenue opportunities. Business insurance policies structured with robust business interruption clauses help cushion these blows, thereby maintaining cash flow.

These policies extend beyond simple revenue reimbursement; they often include coverage for extra expenses that help the business resume operations promptly. This means that while the facility is being restored, additional costs incurred, like renting temporary space or expedited shipping for replacement parts, are also covered.

Liability Coverage and Protecting Against Claims

Liability exposure in bottling plants is diverse. From workplace injuries to product liability, risks must be proactively managed. A comprehensive liability policy protects against claims stemming from staff accidents, third-party property damage, or even contamination concerns. The legal environment in Florida has been reshaped by recent legislative changes, which some experts like Mark Friedlander of the Insurance Information Institute claim has improved the state’s overall risk management culture.

Insurance coverage tailored for liability addresses components such as product recall, environmental liability, and equipment malfunctions that could indirectly cause injuries. Given Florida's regulatory environment, plant managers benefit from policies that also include legal expense insurance to cover potential litigation costs.

This strategic approach not only covers direct claims but also ensures that operational disruptions due to legal disputes are minimized.

Regulatory Considerations in Florida

Florida remains a highly regulated state when it comes to insurance and manufacturing operations. Recent trends indicate that regulatory bodies are gradually shifting the landscape to favor more balanced and profitable insurance practices. For instance, the personal property insurance market in Florida reported its first underwriting profit in eight years in 2024 (AM Best).

For bottling operations, staying updated on legislative changes is crucial. Legislative reforms aimed at curbing legal system abuse have been implemented, leading to a more stable operating environment for residents and businesses alike. Staying compliant with these changes is a key factor in maintaining active and comprehensive policies.

The importance of aligning insurance with current law cannot be overstated. Plant operators must work closely with insurance brokers who understand these regulatory dynamics to craft policies that cater to both operational needs and legal requirements.

Managing Risks in a Volatile Environment

Mitigating Natural Disasters

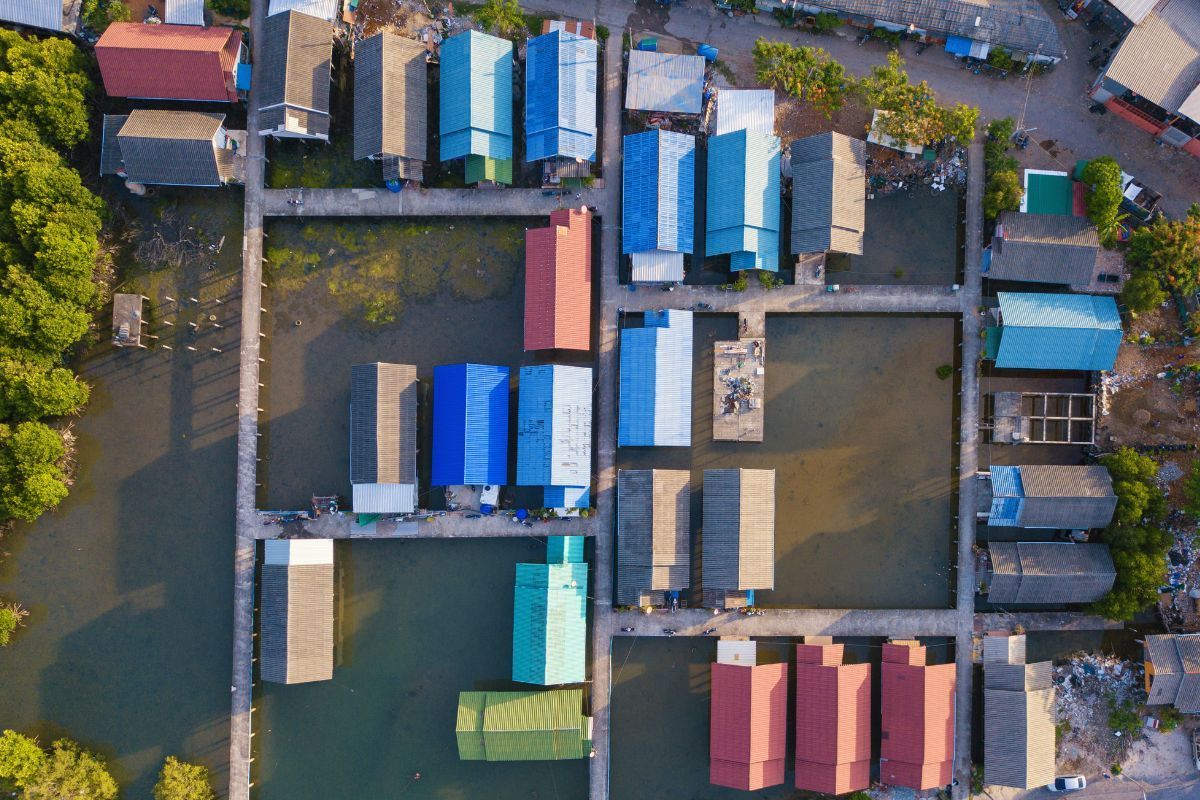

Florida is widely known for its susceptibility to hurricanes and tropical storms. Packaging and bottling plants are often located in areas that experience high winds, flooding, and storm surges. As such, a critical element of any insurance policy in this sector must cover natural disasters. Such policies often include additional perils tailored to Florida’s unique weather patterns.

Discussions with insurers typically highlight the need for coverage adjustments following severe weather events. As industry reports have suggested, carriers increased their reinsurance purchase by an average of 11% for the 2023-24 catastrophe year (Florida regulators), underscoring the heightened risk environment.

Risk managers in bottling plants may also incorporate physical improvements in their facilities such as reinforced construction and upgraded drainage systems, which can be favorably recognized by insurers when calculating premiums.

Addressing Operational and Supply Chain Risks

In addition to natural disasters, operational risks stem from supply chain disruptions and equipment failures. A bottling plant’s efficiency is closely tied to the reliability of its suppliers and the resilience of its machinery. Insurance strategies that include supply chain interruption, contingent business interruption, or equipment breakdown coverage offer extra layers of protection.

Given elevated reinsurance costs and tight profit margins in Florida's insurance market, carefully negotiated claims policies that cover cascading failures within the supply chain are vital. Operators should frequently assess these arrangements to keep up with evolving risk factors in a fast-paced industrial landscape.

This proactive approach to risk mitigation ensures that in the event of a breakdown-be it through supplier issues or internal malfunctions-operational continuity is less severely affected.

Tailoring Insurance Policies to Unique Operational Needs

Customization and Endorsements

One size does not fit all when insuring packaging and bottling facilities. The nature of bottling operations calls for flexibility. Insurance providers offer customization options known as endorsements that can be appended to standard policies, tailoring coverage to address specific risks such as product spoilage, contamination, and mechanical breakdowns.

Recent innovations within the sector include investments in high-tech manufacturing facilities, such as the new 40,000-square-foot facility completed by Sawgrass Nutra Labs in Jacksonville (Sawgrass Nutra Labs). Enhanced facilities bring modern risks, but also the opportunity to incorporate advanced protection measures through policy endorsements.

With customized insurance, plant managers can ensure that specific facets of bottling operations-from automated packaging lines to sophisticated bottling robotics-are adequately covered. Endorsements are designed to bridge the gaps that standard policies leave, making them an integral part of a robust risk management strategy.

Evaluating Providers and Policy Options

Choosing the right insurer calls for a detailed evaluation of a provider’s track record in handling customized commercial policies. In Florida’s competitive market, having an insurer with relevant industry expertise and a track record of fair claim handling is invaluable. Operators should solicit quotes, assess coverage limits, and inquire about additional services such as risk management advice tailored to bottling operations.

It is wise to consult both local experts and national assessors who understand the nuances of Florida’s regulatory environment. With the right insurer, business owners benefit not only from quality coverage but also from strategic insights into reducing risk, thereby lowering operational costs over the long term.

An insurer’s approach to underwriting, especially in scenarios involving high-value equipment and historical loss data, can significantly influence premium rates. Engaging with insurers who have a clear understanding of the unique challenges faced by bottling operations can lead to more favorable policy terms and reduced premium liabilities.

Market Trends and Economic Impact

Florida's beverage industry contributes immensely to the state's economic ecosystem. With over 200 manufacturing, sales, and distribution facilities reported by the Florida Beverage Association, the industry's vibrancy is clear. This robust economic activity fuels a corresponding demand for comprehensive and specialized insurance coverage that can mitigate the risks unique to bottling plants.

Observing market trends offers foresight into the direction of the insurance industry. For example, between 2014 and 2024, there was a significant drop in the number of active home insurance policies statewide (Deep Sky Research). While this statistic pertains to home insurance, it underscores a broader market shift that influences all lines of insurance in Florida. Insurers are recalibrating risk models across the board, meaning that commercial sectors, including bottling operations, are subject to the same rigorous underwriting focus.

This dynamic environment compels operators to be vigilant about policy features that might be adjusted over time due to evolving market conditions. Aligning with providers that offer flexibility and adapting risk management practices are proactive steps in navigating these uncertain regulatory waters.

Risk Management Best Practices for Bottling Operations

Implementing Preventative Measures

Risk management for packaging and bottling plants goes hand in hand with robust insurance coverage. The best strategy involves a blend of physical security measures, rigorous maintenance standards, and regular operational audits. Undertaking routine equipment inspections and reinforcing facility infrastructure can reduce the frequency and severity of claims.

Enhancing facility security through the installation of modern alarm systems, automated shut-off controls on machinery, and comprehensive monitoring systems can also play a pivotal role in preventing incidents that could result in costly downtime. Effective risk management is not only about preventing losses but also about showcasing to insurers that proactive steps are being taken, potentially lowering premiums in the long run.

Facilities that invest in employee training and safety programs tend to fare better during claim reviews. In a state like Florida, where the risk of natural disasters remains high, preparedness and preventive measures are key.

Coordination Between Insurers and Risk Managers

Maintaining strong communication channels between plant management, facility engineers, and the insurer is critical. Periodic reviews of policy terms in light of recent operational changes and risk evaluations ensure that insurance remains aligned with the current state of operations. In some cases, this collaborative engagement can lead to early detection of potential risks before they escalate into major claims.

This active engagement can guide the development of safety protocols and contingency plans tailored to the plant's workflow. As a result, both the insurer and the insured can benefit from enhanced clarity and reduced financial exposure in events of unexpected mishaps.

Regular dialogues with insurers often reveal upcoming changes in market conditions or reinsurance terms, allowing facility managers to adjust safety practices proactively. Such relationships are invaluable particularly during periods of market uncertainty.

The diversity of insurance products available for bottling operations calls for a systematic comparison to understand which options provide the best value and risk coverage. Below is a simplified table that contrasts basic commercial insurance with extended coverage options designed specifically for high-risk bottling facilities.

| Coverage Type | Key Benefits | Scope |

|---|---|---|

| General Liability | Protection against bodily injury and property damage claims | Applies to daily activities and operations |

| Property Insurance | Covers damage to or loss of camp facilities and equipment | Targets physical assets and infrastructure |

| Accident Insurance | Specifically covers injuries sustained during camp activities | Focuses on onsite accidents and injury claims |

| Umbrella Policies | Offers additional layers of protection when basic limits are exceeded | Provides extra coverage across multiple areas |

This chart illustrates that while basic policies may seem cost-effective initially, extended coverage often provides better long-term financial security for operations that face unique bottling risks.

A careful evaluation of pricing strategies, deductibles, and benefit limits is advisable before finalizing an insurance plan. The comparison also highlights the importance of specificity in coverage, ensuring that bottling operations are not left with gaps in their risk management approach.

The rapid pace of technological development in packaging and bottling processes is forcing the industry to adapt quickly. New manufacturing facilities, like those recently introduced by Sawgrass Nutra Labs, signal that technological investment is central to staying competitive in the Florida market. As operational technology evolves, so does the complexity of associated risks.

Modern bottling plants are integrating automated systems and IoT devices to monitor production and facility conditions. These innovations can have a profound effect on underwriting, as they offer real-time data that helps insurers better assess risks. Technological innovations encourage insurers to refine their risk models and provide coverage that aligns with the current state of operations.

Technology-driven solutions in risk management empower facility operators to detect potential failures early. This proactive stance often results in improved underwriting terms and potentially lower premiums. This synergy between technological advances and insurance is key to sustaining steady operations even when unexpected challenges arise.

Challenges and Opportunities in the Current Market

Florida’s insurance market is undergoing significant changes, with recent trends reflecting a balance between emerging challenges and evolving opportunities. One notable trend is that carriers are increasingly investing in reinsurance, evidenced by a reported 11% increase in reinsurance purchases on average for the 2023-24 catastrophe year (Florida regulators). This trend underscores the need for bottling operations to adapt their insurance programs to the changing landscape.

Challenges such as rising reinsurance costs, increased frequency of natural disasters, and shifts in market availability of policies push plant managers to consider both operational adjustments and enhanced insurance coverage. On the flip side, these market adjustments open opportunities for risk management innovations, offering facilities better, more resilient insurance structures.

Plant operators who keep pace with these developments can often negotiate better premiums and benefit from policy enhancements that reflect current risks. A dynamic approach to insurance, anchored by regular policy reviews and adjustments, is essential to overcoming these market challenges.

Steps to Selecting the Right Insurance Policy

Choosing an appropriate insurance policy for packaging and bottling plants requires a well-rounded approach, integrating both risk evaluation and long-term business plans. First, conduct a comprehensive risk audit that covers property, operational, and liability exposures unique to bottling operations. This foundational step ensures that potential vulnerabilities are identified and addressed.

Next, engage with insurers that have a proven record of working with manufacturing and food and beverage sectors. Their experience can provide insights into potential pitfalls and the most efficient way to mitigate them. Considering local market nuances, such as Florida’s recent regulatory and market trends, is essential when selecting an insurer.

Finally, confirm that the chosen policy includes flexibility for endorsements and periodic updates. This ensures that the coverage remains relevant as business operations evolve. A comprehensive policy not only reduces the risk of financial distress during an unexpected event but also preserves the operational integrity of the plant.

Frequently Asked Questions

Frequently Asked Questions help clarify common concerns and address queries that many plant operators might have. The following questions and brief answers are designed to provide clear, succinct insights into bottling plant insurance.

Q: Why is specialized insurance necessary for bottling plants?

A: Bottling plants have unique assets and risk exposures, making customized coverage essential to protect against equipment breakdown, production stoppages, and product liability issues.

Q: Can additional endorsements be added to a standard commercial policy?

A: Yes, endorsements offer tailored coverage for aspects like machinery breakdown, product spoilage, and environmental liabilities that standard policies may not cover.

Q: How do natural disasters affect policy pricing?

A: Natural disasters, such as hurricanes common in Florida, increase risk exposure. This heightened risk often leads insurers to revise premium rates or require additional coverage options.

Q: What steps can be taken to reduce insurance premiums?

A: Facilities that invest in preventive measures like regular maintenance, employee safety training, and facility upgrades can often negotiate more favorable premium rates.

Q: How frequently should a facility review its insurance coverage?

A: Given the dynamic nature of the risks, it is advisable to review and update coverage at least annually or whenever significant changes occur in operations.

Q: How do legislative changes impact insurance policies in Florida?

A: Legislative reforms in Florida have shaped a more balanced insurance market, reducing some of the litigation risks and leading to more stable policy terms.

Preparing for the Future

As the packaging and bottling industry in Florida continues to evolve, facility managers must remain agile in their risk management strategies. The dual impact of technological advancements and increasing market uncertainties drives the need for adaptable and comprehensive insurance programs. Changes in weather patterns, market regulations, and technological adoption all interplay to determine the type of coverage needed to secure long-term operational success.

Staying abreast of industry trends, regulatory updates, and shifting reinsurance costs is crucial. Plant operators should maintain open channels with insurers to understand new opportunities for policy enhancements. As evidenced by recent market shifts-such as the first underwriting profit in Florida's personal property insurance market in 2024 (AM Best)-the environment is evolving in ways that demand flexibility and robust planning.

Furthermore, as market entrants invest in state-of-the-art manufacturing facilities, staying competitive means not only boosting production capacity but also emphasizing risk mitigation. A carefully crafted insurance strategy, supported by continuous operational improvements, provides the dual benefits of safeguarding assets while enhancing business resilience.

Wrapping Things Up

The field of packaging and bottling plant insurance in Florida is intricate, influenced by evolving regulatory frameworks, dynamic market conditions, and operational challenges. Comprehensive coverage that addresses property damage, business interruption, and liability risks is essential for any plant operator. An industry marked by technological innovation, rising reinsurance costs, and a broad spectrum of exposures demands insurance solutions that are both tailored and meticulous.

Plant managers should pursue policies that integrate endorsements and additional coverage options specific to their unique operational risks. Engaging proactively with insurers can lead to more advantageous policy terms, faster claims resolution, and ultimately a more secure operational future. With the industry's substantial contribution forming a pillar of Florida's economic engine, it is clear that protecting bottling facilities is more than an operational necessity-it is a strategic imperative.

To secure continued business growth and reduce financial risks, it is crucial to adopt insurance solutions that respond to both current challenges and potential future events. Partners in risk management and insurance providers who understand the nuances of bottling operations remain invaluable assets in this journey.

Future Outlook for Florida Bottling Operations

Looking forward, bottling plants in Florida are expected to leverage cutting-edge technology and advanced risk management practices to continue refining their operational frameworks. Industry leaders are investing in digital systems that provide real-time insights and predictive analytics, ensuring that potential risks are identified early. This ongoing digital transformation is likely to influence underwriting practices and policy structures significantly.

Moreover, as climate change continues to impact weather patterns, insurers and insured alike will have to contend with more sophisticated strategies to mitigate risks. An emphasis on facility upgrades, enhanced safety protocols, and ongoing employee training will be central to this process. The collaboration between technology and insurance offers a promising avenue for reducing downtime and improving overall operational resilience.

With Florida's beverage sector generating significant revenue and creating numerous job opportunities, the stability and continuity of bottling operations remain a priority. As insurers adapt to a market defined by both volatile weather and rapid technological change, plant operators are encouraged to adopt flexible, forward-thinking insurance solutions. The result will be a more resilient industry capable of thriving even in the face of unexpected challenges.

This discussion on Florida bottling plant insurance highlights the intricate balance between comprehensive coverage and effective risk management. With the right insurance approach, bottling facilities can continue to contribute robustly to the state’s economy while confidently navigating the risks inherent in their operations.

ABOUT THE AUTHOR: PAUL RAMENTOL

I am the Owner and President of Mesa Insurance Agency. I help individuals and business owners across Florida secure personal and business insurance coverage that supports their needs. My focus is on clear guidance, direct communication, and long-term support without call-center delays or confusion.

Contact Us

Personal Coverage Options

Insurance Built for Everyday Protection

Mesa Insurance Agency provides personal insurance coverage designed to support daily life. Our team reviews risks and coverage needs to help clients secure dependable protection at fair rates.

Dental & Vision Insurance

Coverage that helps manage routine dental and vision care costs.

Business Coverage Options

Insurance Built for Business Protection

Mesa Insurance Agency provides business insurance coverage that helps protect operations, employees, and property. We work with multiple carriers to offer coverage options that support daily business activities and long-term stability.

Commercial Auto Insurance

Coverage for business-owned vehicles, drivers, and accident-related liability exposure.

General Liability Insurance

Protection against third-party injury, property damage, and common business liability risks.

Professional Liability Insurance

Coverage for claims related to professional services, advice, or service errors.

Workers’ Compensation Insurance

Coverage that helps support employees with work-related injuries and medical costs.

Commercial Property Insurance

Protection for buildings, equipment, inventory, and physical business assets.

Errors & Omissions Insurance

Coverage for financial losses caused by mistakes, omissions, or service-related claims.

Industries We Serve

Serving Businesses Across Multiple Sectors

Mesa Insurance Agency works with business owners across Florida to provide insurance coverage that supports daily operations. We understand common risks faced by different industries and help clients secure reliable protection.

Construction and Trades Insurance

Coverage for job sites, vehicles, tools, and workplace risks.

Hospitality Businesses Insurance

Insurance for restaurants, bars, and service-based operations.

Retail and

Commercial Properties

Protection for storefronts, inventory, and customer-related liability.

Our Approach

Insurance Made Easy to Understand

Mesa Insurance Agency provides business insurance coverage that helps protect operations, employees, and property. We work with multiple carriers to offer coverage options that support daily business activities and long-term stability.

What makes Mesa Insurance Agency different?

We are an independent agency with access to multiple carriers. This allows us to offer flexible coverage options.

Clients work directly with licensed agents. Service continues beyond the policy start date.

Do you offer coverage for individuals and families?

Yes. We provide personal insurance for individuals and families across Florida.

Coverage includes auto, home, health, life, and flood insurance. Our team explains each option clearly.

Do you work with small and mid-sized businesses?

Yes. We work with businesses of many sizes and industries.

Our team helps identify risks and secure appropriate coverage. Ongoing service is included.

Can I make changes to my policy later?

Yes. Policies can be updated as needs change.

We assist with coverage adjustments, additions, and removals. Clients can contact us directly for help.

Is flood insurance required in Florida?

Flood insurance is not always required, but it is strongly recommended in many areas.

Standard home insurance does not cover flood damage. Our team can review your flood risk and options.

How do I contact your office?

You can contact us by phone, email, or through our website.

Our team responds promptly during business hours. Support is always available when needed.

From the Blog

Insurance Topics That Matter

Clear answers for common questions.

Client Reviews

Trusted by Clients Across Florida

Mesa Insurance Agency is proud to serve individuals and businesses throughout Florida. Clients choose us for clear communication, responsive service, and reliable insurance support. Their feedback reflects our focus on long-term relationships and consistent service.

Contact Us